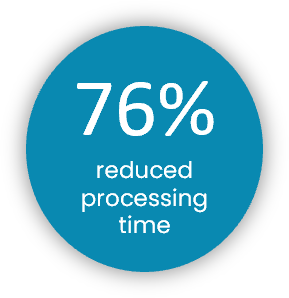

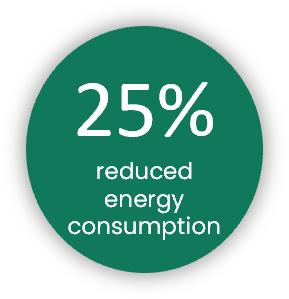

where our particle analysis has facilitated

substantial operational improvements

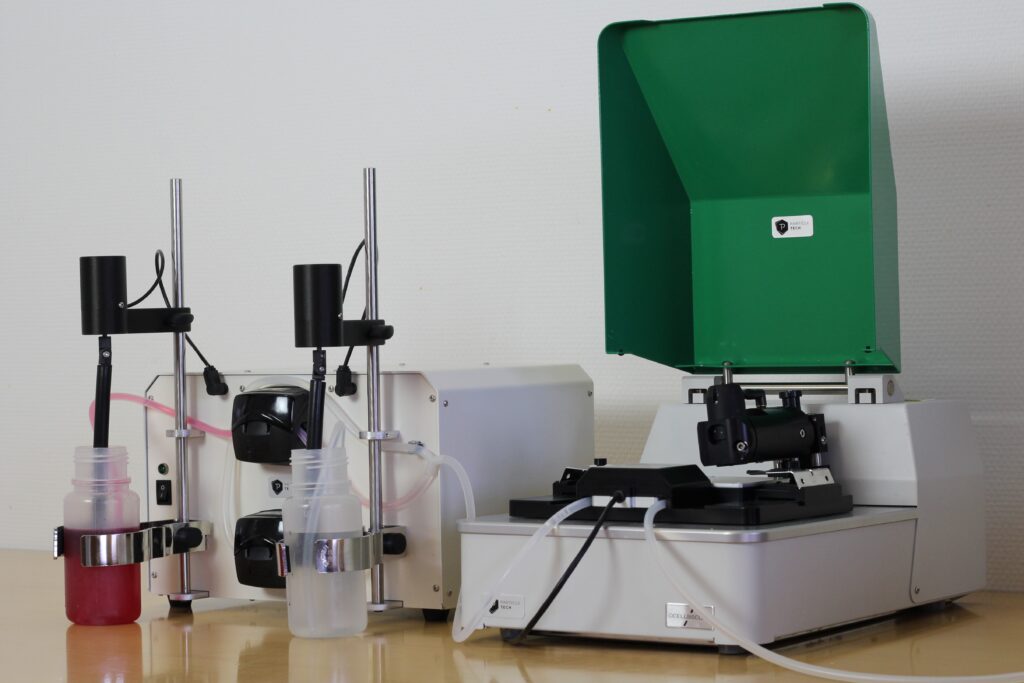

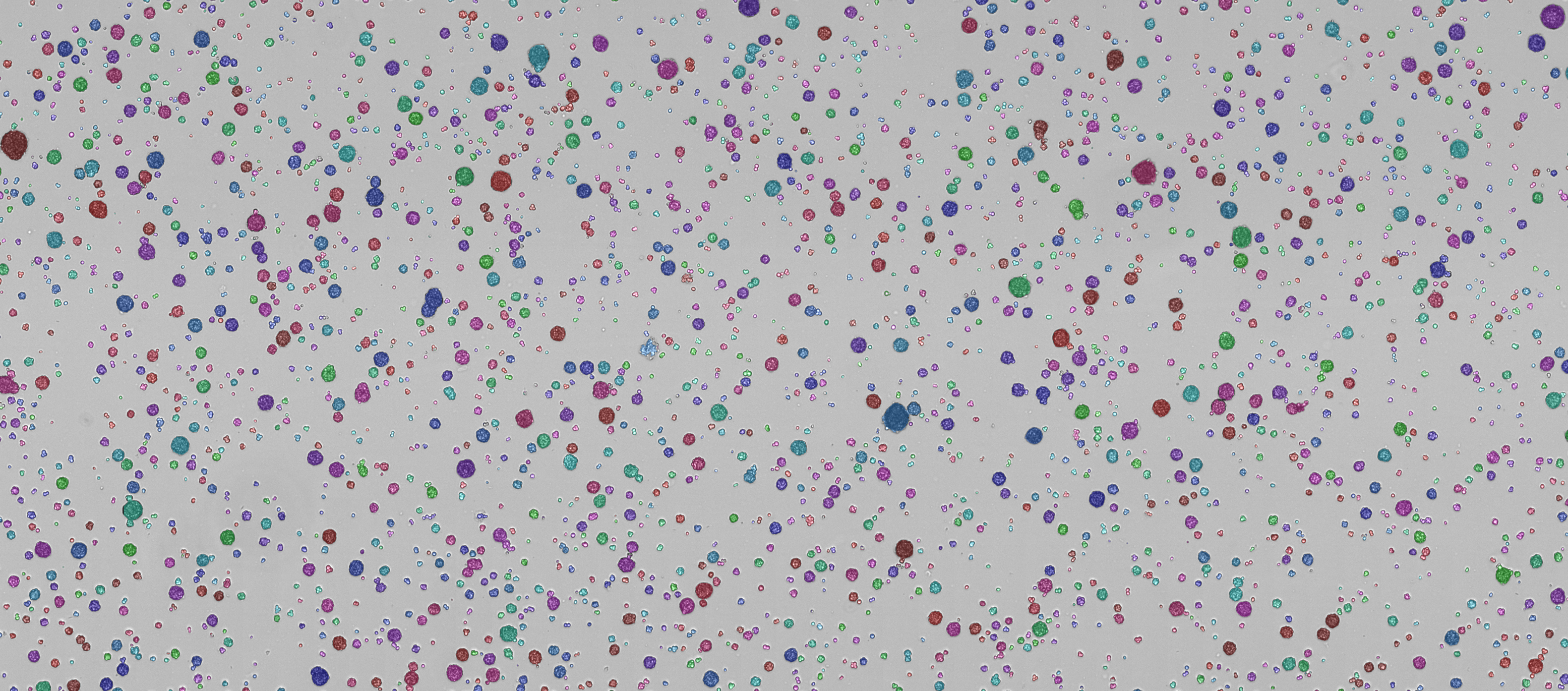

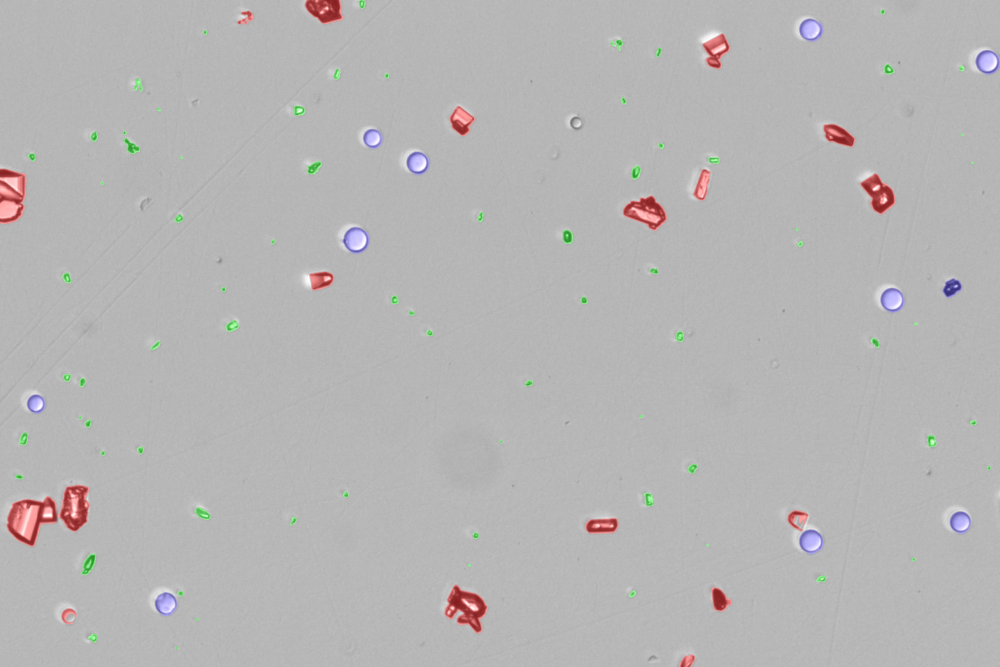

Particles in Suspension

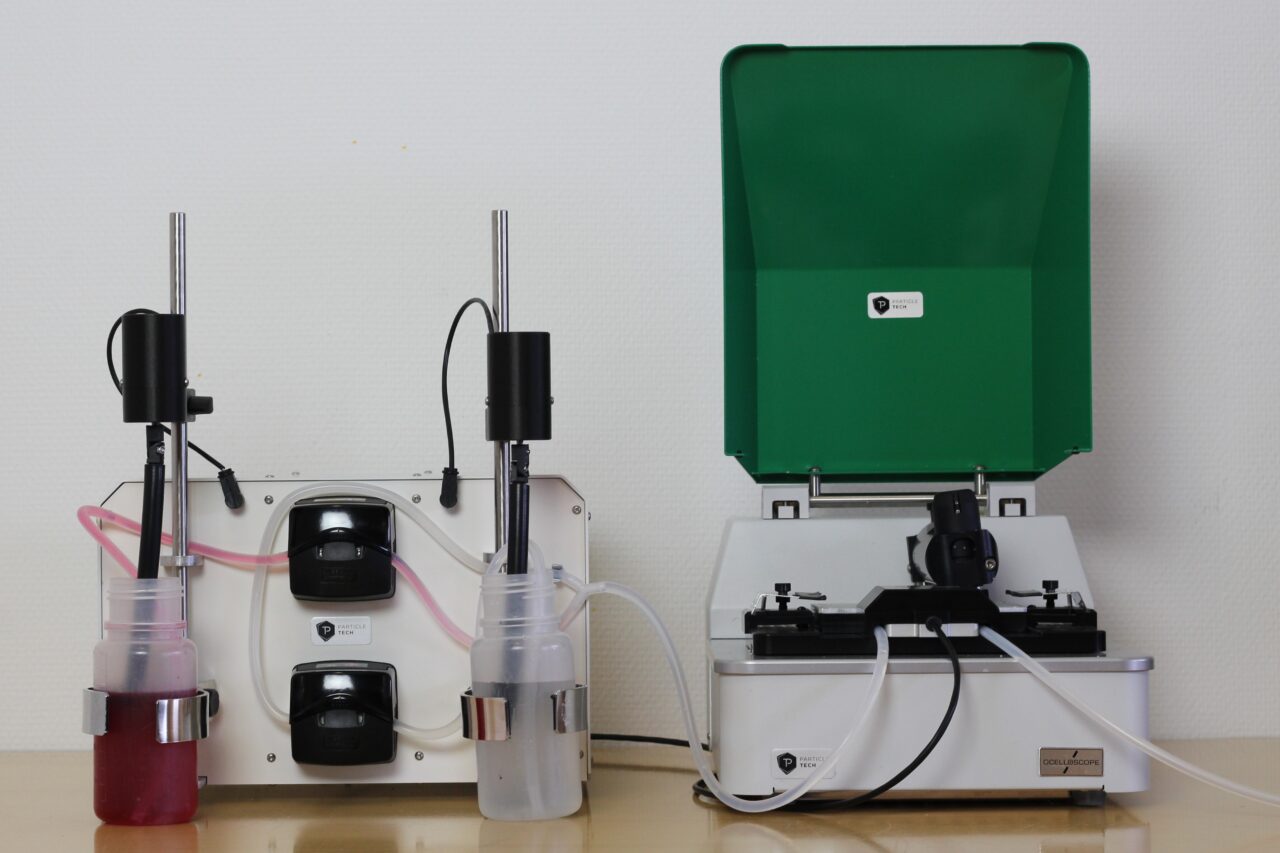

ParticleTech offers you real-time measurements in an automated flow system for continuous monitoring of processes like crystallization and fermentation. Now you can react fast to changes in production.

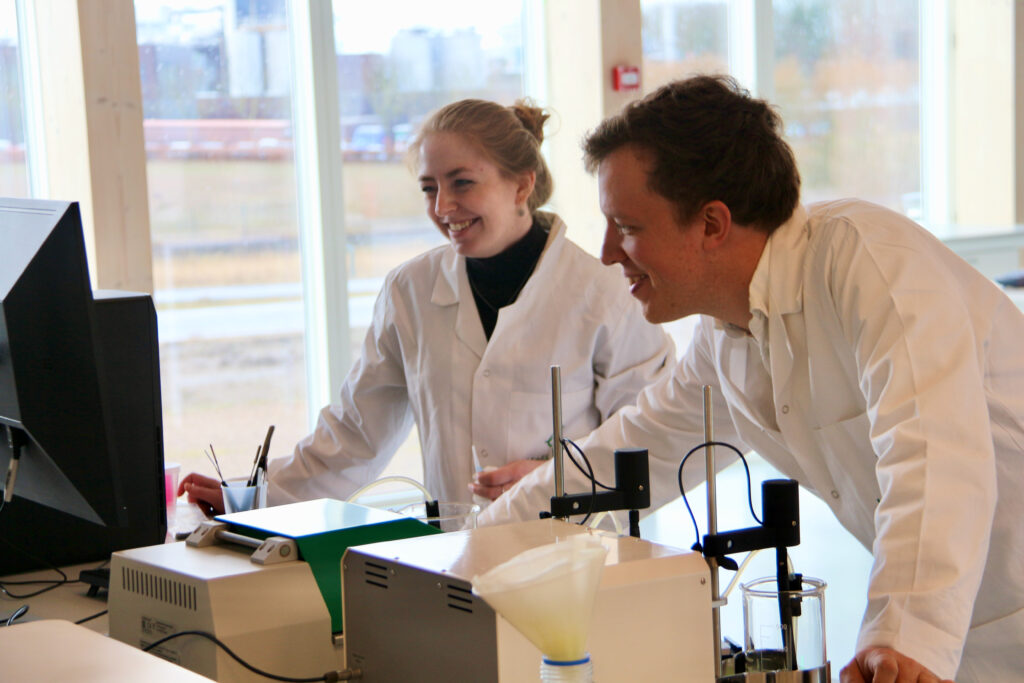

Helix Lab collaboration

We are happy to announce our collaboration with Helix Lab. In two Fellowship projects ParticleTech Solution is key technology. The projects are within crystallization and flocculation.

Oil Crystallization

Know your crystallization process better: Find out exactly when crystal growth peaks and the process is done. You will save production time up to many hours and at the same time increase product quality.

Customer feedback

We have worked closely with ParticleTech and incorporated their technology in our research to tackle some of the most challenging problems in particle monitoring technology. We look forward to many more years of co-development and research with them

Thank you ParticleTech for the Sugar Analyser, which has added much value to my work, and for the excellent service!

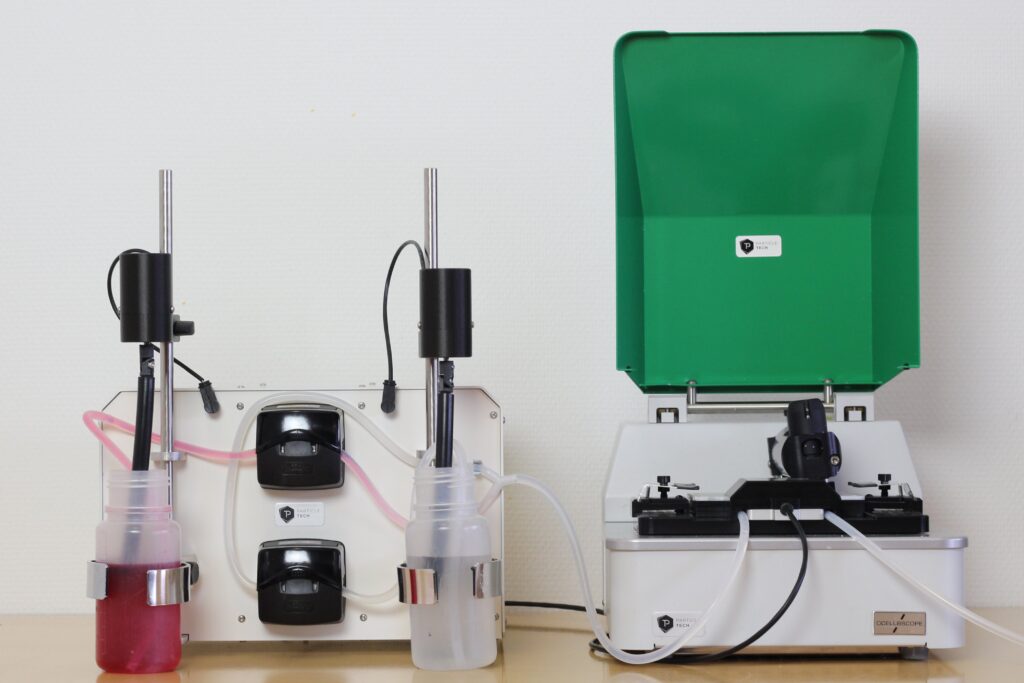

ParticleTech Analyser

ParticleTech Analyser will enable you to optimize your production processes to gain higher yield, achieve increased product quality, spend less production time and reduce energy consumption.

ParticleTech develops and supplies a measurement and analytical solution for industrial particles, based on high quality optical scanning and real-time image analysis.

ParticleTech Solution offers a fast and cost-effective alternative for process monitoring, which can be used at any stage of the production and provide an early and accurate overview of the process. It is a non-invasive technology for at-line measurements in the food, pharma and biotech industries.

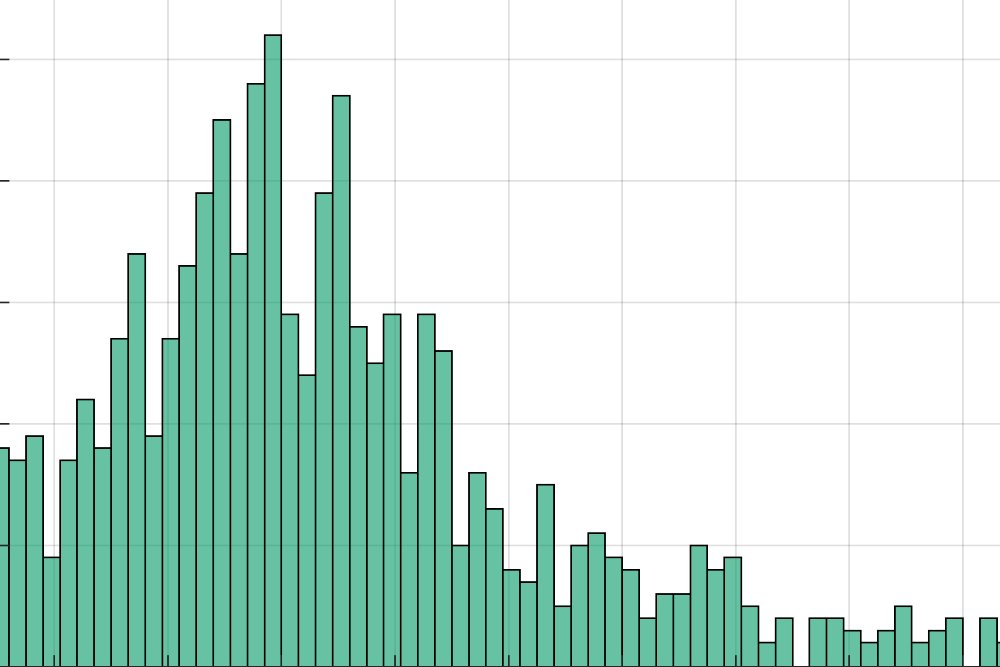

Particle size distribution (PSD)

ParticleTech Analyser measures size distribution of particles such as crystals, cells and flocs. Choose your own output in the software based on standard features like Area, Circularity, maximum diameter, etc.

Particle count/concentration

Using ParticleTech Flow Cell and advanced 3-D segmentation algorithms all particles in the flow cell are measured. For fermentation this means providing the exact number of cells per microliter (µl).

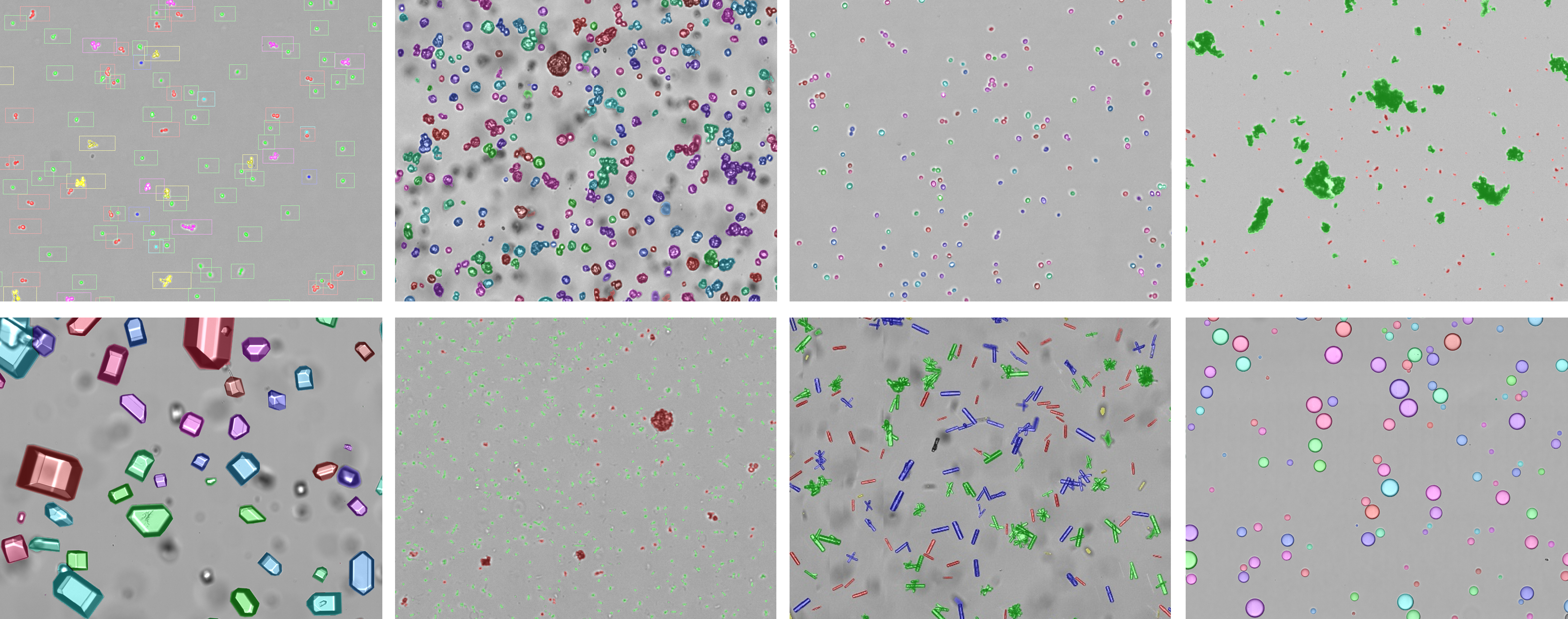

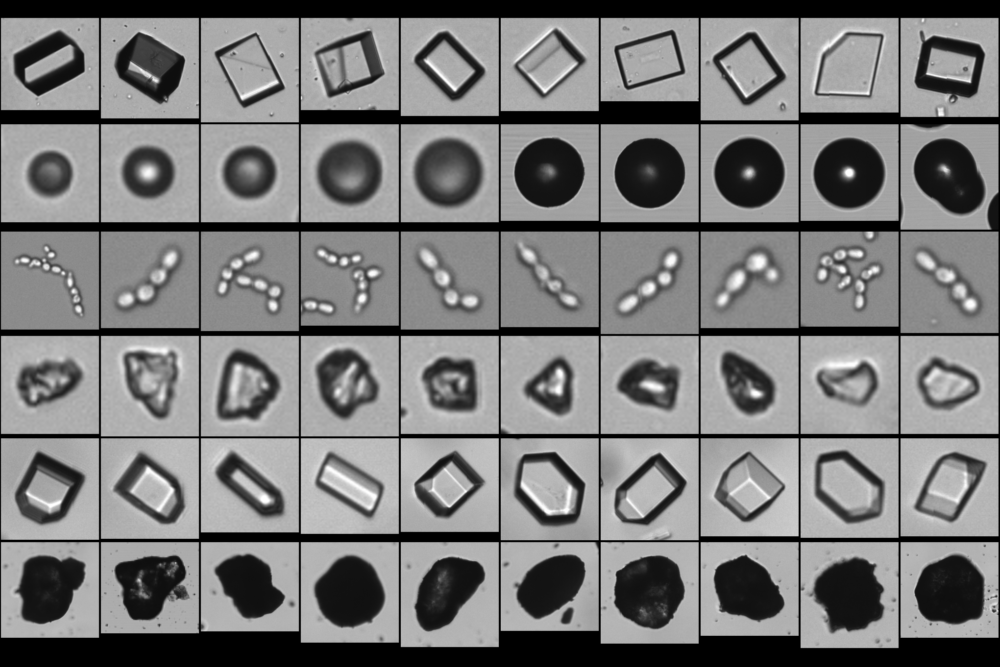

Morphology/shape

In addition to traditional PSD we provide info on particle shape. Ex: A rough and a smooth sand grain can give same circularity results. We will give you exact shape results as to the roughness as well.

Classification

The ParticleTech Classification algorithms are efficient tools for distinguishing different particles based on e.g. size, shape, and transparency. We identify each class by adding a specific color per class.

Fast, accurate, & reliable

ParticleTech Analyser is easy to use and results are provided very fast. Accurate data output is giving within 1-2 minutes from sample is inserted. Measurement results are repeatable and reliable.

User-friendly software

Operators in busy production environments use ParticleTech Software. Our solution including pumps, stirrers, cleansing program for cleaning flow cells and tubes are automated in easy-to-use software.

Advanced algorithms

Advanced algorithms are continuously developed and our Algorithm Library consist of a huge variation of algorithms to identify crystals, cells, flocs and perform classification, 3-D segmentation, etc.

Customized solutions

Innovation is driven by the needs of our customers. We always strive for a close and continues collaboration with our customers and we always do our utmost to give the optimal solution for each customer.

Let’s test your sample!

Find the best way of supporting your process optimization starts with measurements of your products.

We can come to your production or you can send us samples to test in our laboratories.